Article of the Month -

June 2009

|

Push the Button – or Does the

“Art of Measurement” Still Exist

Prof. Dr.-Ing. Rudolf STAIGER

University of Applied Sciences Bochum, Germany

Chair of FIG Commission 5

This article in .pdf-format (17

pages and 1251 KB)

This article in .pdf-format (17

pages and 1251 KB)

1) This paper has been prepared and

presented as a keynote presentation in Plenary Session 3 – GNSS,

Geo-sciences and Surveying at the FIG Working Week 2009 in Eilat,

Israel, 7 May 2009.

Key words: art of measurement, technological change, skills

for surveying, measurement process, surveying measurements.

SUMMARY

The entire geodetic measurement technique has changed significantly

during the last 30 years. In former days the observations were tedious

and cumbersome; the quality of the measurements depended directly on the

capabilities of the observer. Today our surveying instruments are

automatic measuring devices; their results no longer depend on the sharp

eyes of users. “Measurements are so easy – just push the button.” This

is one important advertising slogan used by all the manufacturers. And

it describes the reality: we do not know what is going on inside our

instruments, but today the data acquisition itself is easier and much

more efficient than it was in past decades. The flow of our data is

automatic, as is the entire process of data treatment and calculation.

So is there any “art of measurement” left or still needed?

In order to answer this question the different eras of surveying will

be described and analyzed carefully. Data acquisition has become much

easier, but this does not mean that our measurement results are

error-free. Nor does it mean that we control the entire measurement

process! Are there still mistakes in our data? How do we have to control

our measurements in order to prevent undetected outliers or significant

systematic deviations? Can we estimate our overall precision and

accuracy?

The art of measurement still exists, but it is different from the

traditional one. It consists, very generally speaking, in the successful

design and control of the entire measurement process. What this means

will be explained in detail. And it will certainly be much more than

just “pushing the button”.

ZUSAMMENFASSUNG

Die geodätische Messtechnik hat sich in den letzten 30 Jahren stark

gewandelt. Aufgrund der vielen Innovationen durch die Hersteller, ist

die Datenerfassung und -auswertung viel einfacher und effizienter

geworden. Gleichzeitig ist der direkte Einfluss des Anwenders auf die

Ergebnisse stark zurückgegangen. Die Kunst des Messens besteht heute

nicht mehr im „sorgfältigen Koinzidieren und Anzielen“, sondern in der

Beherrschung des gesamten Mess- und Auswerteprozesses von der Planung

bis zum Endergebnis. Dabei ist ein besonderer Augenmerk auf eine

umfassende und möglichst unabhängige Kontrolle des gesamten

Messprojektes zu richten.

1. INTRODUCTION

“Measurements are so easy – just push the button.” This is one

important message from numerous advertising slogans for surveying

equipment. In reality, the acquisition of surveying data is much easier

and faster today than it was 30 years ago. This is thanks to ongoing

development of the main instruments (total stations, digital levels, and

GNSS-receivers) by all manufacturers. As measurements are so easy to

achieve there are several questions to raise:

- What is the value of the science of measurement, when the data

acquisition is so easy?

- Which knowledge and capabilities must a surveying engineer

possess nowadays to use geodetic instruments successfully?

- Does the “art of measurement” still exist? Or is everybody today

capable of acquiring and treating geodetic data without specific

skills or profound knowledge of surveying?

In order to answer these questions, we will begin with a short review

of the different eras of surveying instruments. Thereafter the actual

situation will be analyzed from different points of view, and finally

the “art of measurement” will be discussed.

1.1 In fact – What is Measuring?

Leonard Euler (1701–1783) described the process of measurement:

“There is only one way to determine and size a value. We have to compare

it with a known size of the same type.” This more than 250 year old

definition is still valid today. The famous Swiss mathematician

continued by saying: “Physics is nothing else than a science, looking

for methods for the measurement of values”. Metrology is the science of

accurate measurements and as such probably as old as mankind. The German

scientist Hermann von Helmholtz founded modern metrology by defining a

consistent methodology for all type of measurements in the natural

sciences (HELMHOLTZ, 1887).

The reasons for executing measurements are manifold. The main causes

are the search for:

- Increased knowledge and cognition. The science of

measurement is indispensable and plays a fundamental role in all

natural sciences.

- More objectivity and consumer protection. All goods and

services on the public market are quantified today in standardized

units and in most of our countries are under strict public control.

- Automation, quality control, and quality improvement of

technical processes. A key element in the fully automated

production of parts or entire products is so-called production

measurement technology, which is an essential precondition for an

automated industrial production.

- Security. Passenger transportation systems of all kind

(airplanes, trains, ships, cars, aerial railways, elevators, etc.)

are using sophisticated measurement systems in order to assure safe

and comfortable transport.

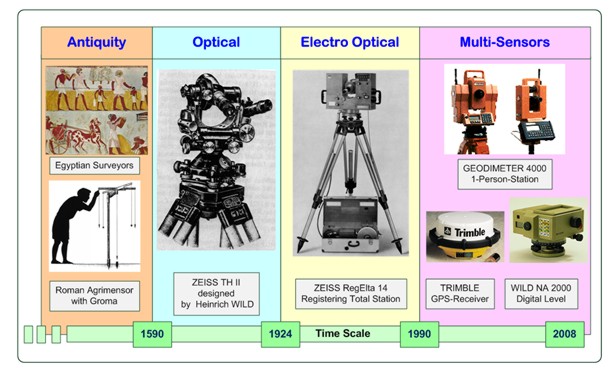

1.2 The Historical Development of Surveying Instruments

Measuring and surveying are not only activities which have been

performed for thousands of years; they are furthermore an important part

of our history of civilization. The technical development of surveying

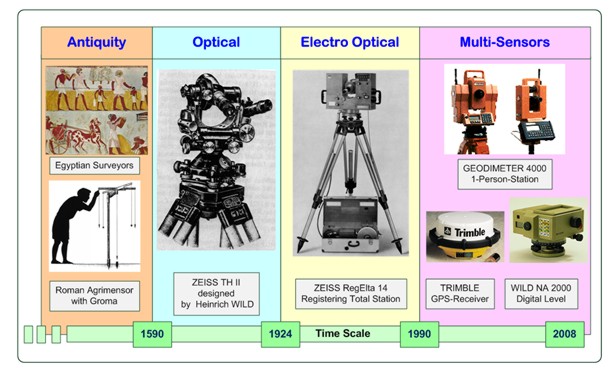

instruments can be divided roughly into four different phases (Fig. 1).

The archaic Phase lasted thousands of years and ended in 1590 with the

invention of the telescope.

Fig. 1: The four different phases of surveying instruments

The following Optical Era persisted for more than 300 years and had

its peak at the end in around 1920 with the presentation of the first

modern theodolite, Zeiss TH II, designed by the ingenious Swiss inventor

Heinrich Wild. The technical progress during the Electro-Optical Phase

was tremendous. At the end of the 1980s most electronic total stations

offered coaxial (angle and distance) measurements, were equipped with a

compensator, and allowed digital storage of the measured points.

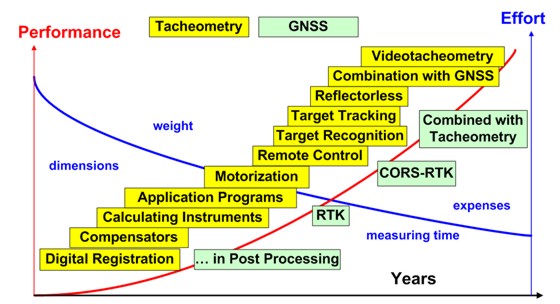

1990 started the Phase of Multi-Sensor-Systems, which continues

today. In this year the first digital level (WILD NA 2000) and the first

motorized total station (GEODIMETER 4000) were presented. At the same

time the GPS was announced as the new universal positioning technique,

which makes traditional instruments like total stations needless. In the

following years, all types of geodetic instruments were improved in

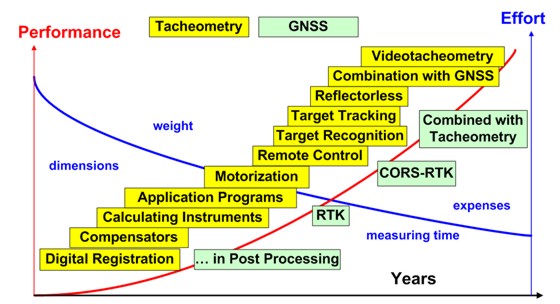

respect of greater efficiency and new functionalities. Figure 2 shows

the progress of total stations and GNSS-receivers. It is interesting to

note that instead of talking about the substitution of tacheometry by

satellite based systems everybody is actually propagating the combined

use of both technologies.

Fig. 2: The different steps of progress for tacheometry and GNSS

during the last 20 years.

2. SURVEYING INSTRUMENTS TODAY

The main instruments of the surveyor nowadays are the digital level,

the total station, and the GNSS-receiver.

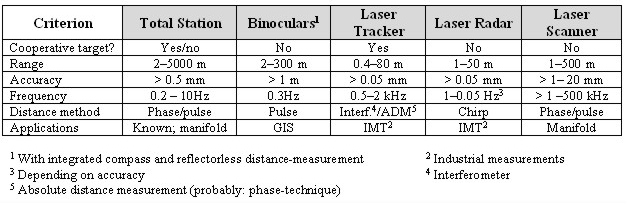

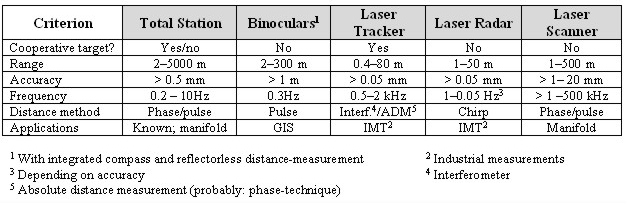

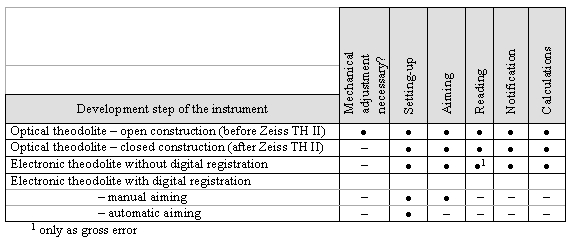

Table 1: Different realizations of the combined use of angles and

distances

The combined measurement of angles and distances deliver polar

coordinates in the two- or three-dimensional space. Based on this

principle we find different types of instruments (Table 1).

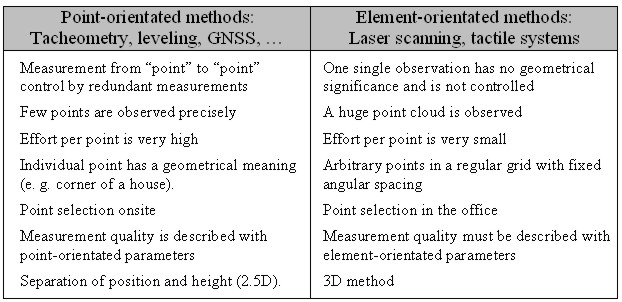

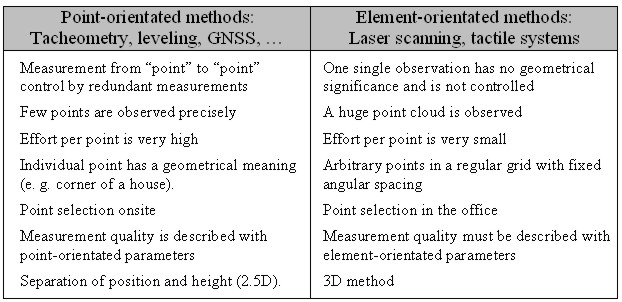

Terrestrial laser scanning (TLS) is in theory also part of the

polar-coordinate-family, but the use and the applications themselves are

quite different from those of the other instruments. The traditional

acquisition methods of the surveyor are “point-orientated”, while TLS

has to be considered as an “element-orientated” approach. The invention

of electronic total stations and GNSS-receivers led to the substitution

of existing measurement systems. Methods of measuring points were

replaced by other methods which are more accurate and more efficient

(Table 2).

Table 2: Principal differences between point-orientated and

element-orientated measurements

For laser scanners the situation is different. With their

capabilities – digitizing entire objects in detail – they enlarge the

“tool-box” of the surveyor. New applications and innovative products can

be realized which would not have been feasible with traditional

surveying equipment due to economical or technical limitations.

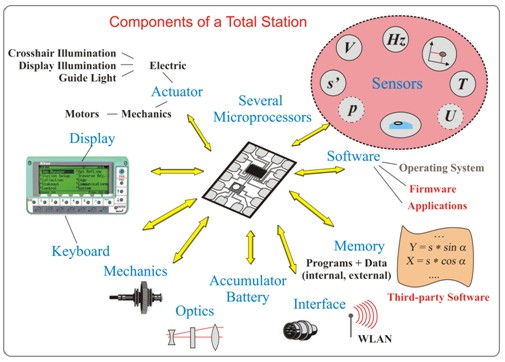

2.1 Characterization of the Actual Surveying Equipment

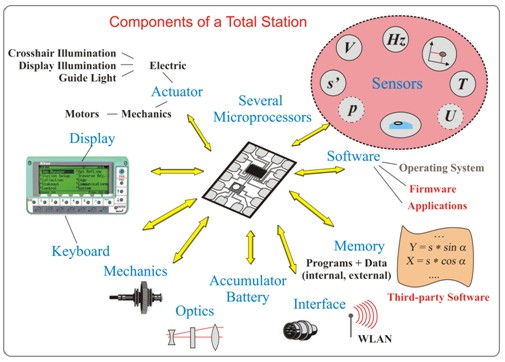

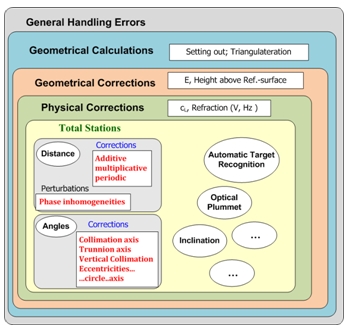

We have noticed an enormous increase in functionality during the last

20 years thanks to manufacturers. All actual measurement systems are

multi-sensor-systems, which are equipped with several sensors and driven

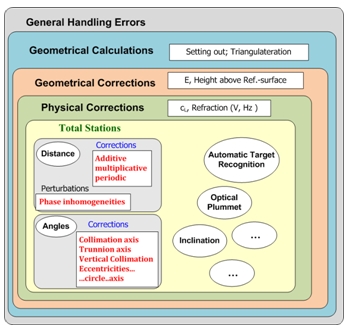

by one or more microprocessors (Fig. 3). Raw observation values as we

know them, for example from angular observations with an optical

theodolite, no longer exist. The actual values shown on the display of

the instrument are the result of multiple sensor readings, modified by a

range of geometrical and physical parameters. These correction

parameters and the entire correction model are not accessible to the

user. The multiple sensor readings are used for the validation of the

measurement itself (detection of outliers, beam interruption, etc.) and

at the same time for an increase in accuracy.

Fig. 3: Components of a modern total station

A modern total station is nothing more than a mobile PC with

geometrical sensors. The observer (with a direct influence on the

measurement) is downgraded to the user of a system. The internal

processes remain hidden and the manufacturers do not publish information

about the technologies used in their instruments. Today many instruments

can also be used as autonomous remote controlled measurement devices.

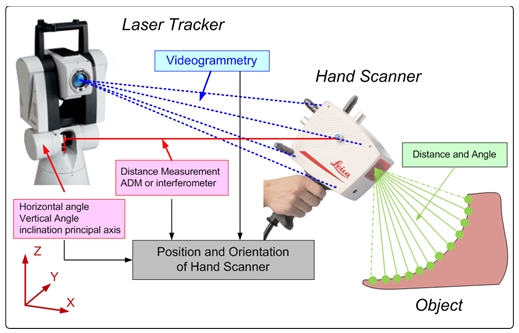

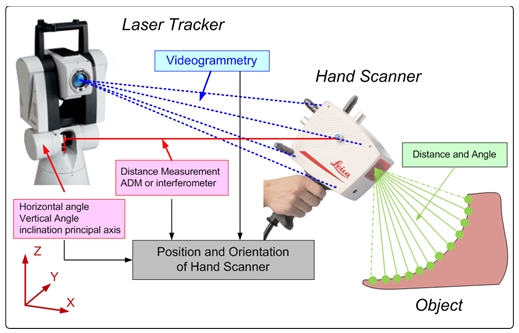

Fig. 4: Laser tracker with hand scanner as an example of a

multi-sensor-system

A laser tracker combined with a hand scanner is a good example of the

complexity of the actual measurement systems (Fig. 4). The determination

of the position and orientation of the hand scanner relative to the

tracker is realized in real-time with measured angles and distances

(position) combined with videogrammetry (orientation). The coordinates

of the object are determined in relation to the actual position and

orientation of the hand scanner.

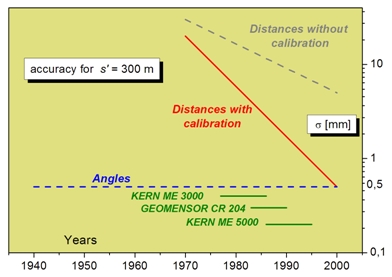

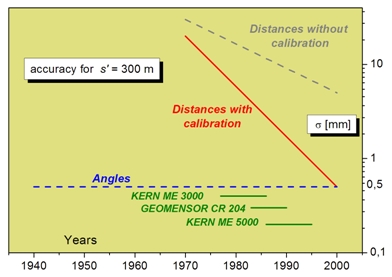

During the last 70 years the accuracy of our measurement systems has

not always been improved. Height determination became faster and simpler

with the introduction of digital levels, but there has been no systemic

enhancement of accuracy. The situation for the measurement of directions

and angles is quite similar. In contrast to this are electronically

measured distances: we note that there has been a significant

advancement in precision and accuracy.

Fig. 5: Development of accuracy of angles and distances for a

distance of 300 m.

2.2 Measuring – the Customer’s View

The measurement techniques and applications have changed

significantly. The main characteristics are:

- The customer is using instruments like a black box. This

means he or she has, in general, no idea about the internal

technical processes of the instrument. The functionality of the

system and the software is so extensive that he or she is using only

a small fraction of it.

- Eighty per cent of the measurements are not controlled.

- The user is convinced that the results are “true”, and

does not care for a regular check of the entire equipment.

- The life cycle of a specific instrument (normally three

to five years) is in general too short for the user.

2.3 Measuring – the Manufacturer’s View

During recent decades we have observed a strong concentration in the

market. Today LEICA, TOPCON, and TRIMBLE share the world market between

them. Economically, “surveying” is not easy as a business. On the one

hand there are only a few vendors, but on the other hand the clients are

demanding and not always investment-friendly and the whole branch is not

considered a growth sector. The main aspects for the vendors are:

- Actual measuring systems are powerful, reliable, and

easy-to-use.

- The manufacturers are confronted with product piracy from

China.

- There are different reasons why a new product or model

appears on the market, but only the first of the listed reasons is

obvious to the user.

- Innovation. A new functionality is introduced onto

the market, for example, automatic target recognition or

automatic target tracking.

- Non-availability of electronic components. If the

OEM-components are no longer available the manufacturer is

forced to redesign its instrument, despite the fact that there

is no need from the customer’s point of view.

- Reduction in manufacturing costs. In order to reduce

the production costs, manufacturers revise their products. Often

only a complete redesign leads to the desired results.

- Not every product which could be developed technically appears

as a product on the market. The (potential) economical success (or

return on investment, ROI) in relation to the costs of development

must be promising, otherwise the idea will not become a real

product. Two examples will clarify this statement.

- Fully automated leveling system. All manufacturers

have the technical potential to develop a fully automated

leveling system. The only manual operation would be the rough

setup of the instrument and the rods. The rest (leveling of the

instrument, searching for the rods, focusing, measuring,

calculating, etc.) could be fully automated.

- Precise distance measurements. The most accurate

geodetic distance measurement device is the KERN Mekometer ME

5000 (cf. Fig. 5). It can only measure distances and a single

measurement lasts about two minutes. Today it would be possible

to integrate this technology into a total station and to achieve

similar results with it within a fraction of a second.

2.4 Measuring – the Metrologist’s View

Metrology is the science of measurements. One important task of

metrology is to ensure worldwide uniformity of measurements and their

traceability to the International System of Units (SI). From this point

of view it can be stated that:

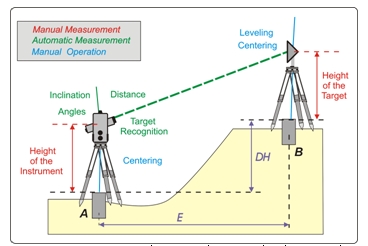

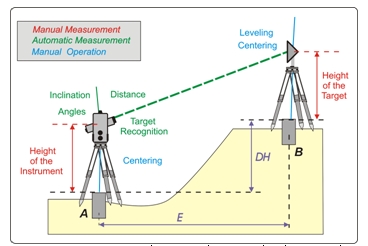

- All new instruments fulfil the manufacturers’ geometrical

specifications.

- Despite the high grade of automation, our results are still

influenced directly and indirectly by the user. Considering the

standard task “determination of the geometrical relationship between

the ground points A and B” (Fig. 6a), we discover that besides the

measurements themselves there are the manual operations: centering,

leveling, and height determination of the targets and the

instrument. If we execute this task with satellite based systems

(GNSS), the necessary manual operations and measurements remain the

same.

Fig. 6a: Measurements between the ground points A and B.

In addition we have to consider the correctness of the parameters for

instrumental, geometrical, and physical corrections as well as all the

steps of geodetic calculation executed with the instrument (Fig. 6b).

Fig. 6b: Shell-model of possible errors for a total station.

- Geodetic measurements are not always traceable to SI-Units.

- The specifications regarding the accuracy and

reliability of GNSS-measurements are in general very vague and

not satisfying. These measurements are subject to a variety of

external influences, like satellite constellation, accuracy of orbit

parameters, multipath effects, and the influence of the ionosphere.

The quality of the point determination depends not only on these

factors but also on the time and duration of the observation itself.

These circumstances are already observable on studying the footnotes

of the technical specifications of GNSS-receivers: “Accuracy and

reliability may be subject to anomalies due to multipaths,

obstructions, and satellite geometry. Always follow recommended

survey practices.”

2.5 The Limits of Accuracy

A measuring system consists of all the components which contribute to

the final result. It is constructed not only of the instrument including

the accessories but also of the quantity to be measured, the physical

environment, the observer (user), and finally the measurement and

calculation method in use. If we want to indicate an overall accuracy we

have to consider the whole system.

2.5.1 The limits of accuracy in the past

In former days, achievable measurement accuracy was limited mainly by

the observer and his imprecise surveying equipment. Some characteristics

typical of that time were as follows:

- The observer had a direct influence on the quality of the

measurements (pointing, bringing into coincidence, reading, …).

Surveying was a handcraft, demanding a lot of experience and skills.

- The accuracy of one single measurement was in general not

sufficient. Therefore repetitions became mandatory. This also led to

several useful side-effects:

- Outliers could be detected.

- The differences between the measurements also served as

immediate indicators of the actual repeatability.

- The accuracy was improved not only by repetitions but also by

well-considered observation sequences. Everybody knows that the

angle measurement on both faces included the reversed observation

sequence on the second face. The benefit of such a sequence is the

elimination of systematic error influences (in this case the “tripod

distortion”).

2.5.2 The limits of accuracy in the present

With the current generation of surveying equipment precise

measurements are easy to achieve, but the user often underestimates the

risk of possible errors. The components physical environment and

equipment are actually limiting our achievable accuracy:

- Physical environment. Here the influence of the

atmosphere on our measurements is the main focus. Refraction is

limiting the accuracy of observed horizontal and vertical angles as

well as determined distances. During the last 20 years,

manufacturers have improved the accuracy of measured distances by a

factor of 5 to 10. In order to also make use of this accuracy for

longer distances (s > 200 m) we must determine the representative

meteorological parameters (air temperature and air pressure) very

accurately onsite. If a distance of about 500 m is to be determined

with an accuracy of 0.5 mm, the representative air temperature must

be known with an uncertainty smaller than 1 °C!

- Measurement equipment. Manufacturers have improved

instruments during recent decades, but not all accessories have been

adapted to this progress:

- Tripods. Different investigations indicate

significant vibrations (INGENSAND, 2001) and horizontal torsions

(DEPENTHAL, 2004) when motorized total stations are used in

combination with normal tripods. But vendors are not offering or

even promoting high quality tripods which fulfil the special

needs of motorized instruments.

- Optical plummets. Today we can measure in limited

areas (s < 150 m) “below the millimeter”. The transfer of these

highly accurate measurements onto the benchmarks fails due to

optical plummets, which have not improved in accuracy during the

last decades.

Today, fieldwork is not always exercised with reasonable care. The

user is convinced that his instrument is error-free and that no special

treatment such as protection against direct sunlight is necessary. In

contrast to this behavior are investigations which indicate clearly that

digital levels show significantly bigger variations in the line of sight

– due to changes in the temperature of the instrument – than optical

levels (STAIGER, 1998). If a survey umbrella is not in use, additional

effects occur due to one-sided heating caused by sunlight.

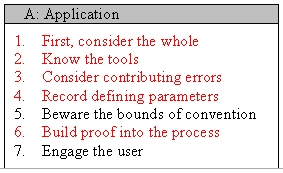

3. AGELESS PRINCIPLES IN SURVEYING

If we are searching for ageless principles for geodetic measurements,

it is hard to find recommendations in the educational books or in the

technical literature. “The ABC of x, y, z”, presented by Peter Byrne and

Gail Kelly at the FIG Working Week in Hong Kong, is one of the rare

papers dedicated to this subject (BYRNE and KELLY, 2007).

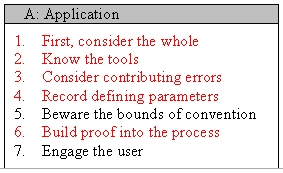

Table 3: The seven principles of professional surveying

The authors are publishing in essence 21 principles of professional

surveying, divided into three categories: application, behavior, and

context. Measurements are treated under category A (Tab. 3), where the

relationship with the science and the technology is discussed. Five out

of these seven rules are directly related to the acquisition and

treatment of geodetic data:

- First, consider the whole. “Working from the whole to the

part” is a well recognised surveying principle – working within the

control system, interpolation contains errors, extrapolation

amplifies them. Modern surveying technologies are such that the

“whole” (the control system) may be found to be deficient. The

“parts” (actual measurements) are of higher quality than the whole.

This may require the surveyor to consider changing the whole to fit

the principle of the parts.

- Know the tools. This principle is more important than

ever before. It is not sufficient to read the data sheet and to

listen to the vendor’s promises. As our measurement systems become

more opaque (black box systems) the necessity of regular and

meaningful checks increases. For complex systems like GNSS-receivers

we can only proof the entire measurement system by comparing the

final results with nominal values.

- Consider and analyze contributing errors. In most

applications there will be an expected accuracy of objects in space.

Uncertainties come from a number of sources, and they need to be

assessed and analyzed with respect to the unknown values. This

analysis is part of the design process before the real measurements

and part of the validation process after the measurements.

- Record the defining parameters. Record the adoption and

the transformation into the existing coordinate system. This makes

the whole survey traceable.

- Build proof into the process. A non-surveyor expects

reliability and accuracy from our profession. Today we have

efficient and accurate measuring systems, but this does not imply

that our measurements and the final results are error-free. We have

to proof our work with regular external checks. Repetitions control

only the measurement as such, not the whole process! The best

control for the entire work and the final results is checks which

are independent from the production methods.

Our modern and efficient equipment, which is at the same time easy to

use, seduces us towards the misapprehension: “External checks of our

work and our results are no longer necessary”. The above analysis

reveals the opposite. External overall checks of our work are of

particular importance today.

All rules which are in direct relation to the measurements can be

summarized by the request: “Master the entire measurement process”. All

rules are ageless, because there is no direct relation to a specific

step of technical development. Every user has to transform this general

rule into specific measures depending on the actual measurement task.

Mastering the entire process also comprises:

- choosing the optimal method of data acquisition and data

analysis

- mastering the data acquisition and data analysis, which means:

- the design of an appropriate strategy for acquisition and

analysis,

- the check of the survey equipment and the data

(observations), and

- the check and the validation of the entire system and the

final results.

4. THE ART OF MEASUREMENT

4.1 The Art of Measurement in the Past

Three hundred years ago there must already have been discussions

about the necessary qualifications of a surveyor: why else did the Swiss

mathematician Jacob Bernoulli say in 1684: “Surveying can only be

practiced correctly by somebody who has experiences in mathematics.

Therefore the state should not delegate this task – in contradiction to

a curious prejudice – to uneducated and ordinary people”?

The traditional fieldwork necessitated great versatility. The

surveyor in charge needed:

- Capabilities for carrying out precision mechanical work.

This was necessary for the setting-up and adjustment of the

instrument on every station.

- Skills in calculating.

- Sharp-sighted eyes.

- Physical robustness against unfriendly weather

conditions.

The requirement profile for field personnel became – with the

stepwise modernization of our instruments (cf. Fig. 1) – smaller and

smaller. If we measure with automated target recognition devices today,

only the need for physical robustness remains. And this requirement is

also weakened because observation times are shorter now than they were

in the past.

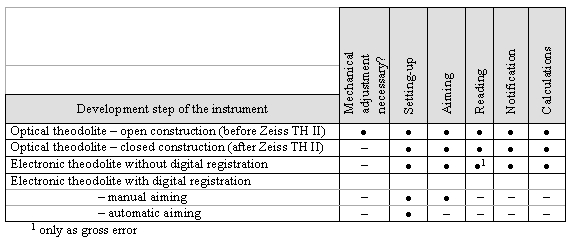

The observer’s influence on the observed angles is described in Table

4 according to the capabilities of his instrument.

Table 4: The observer’s influence on the results of angular

observations

4.2 The Art of Measurement in the Present

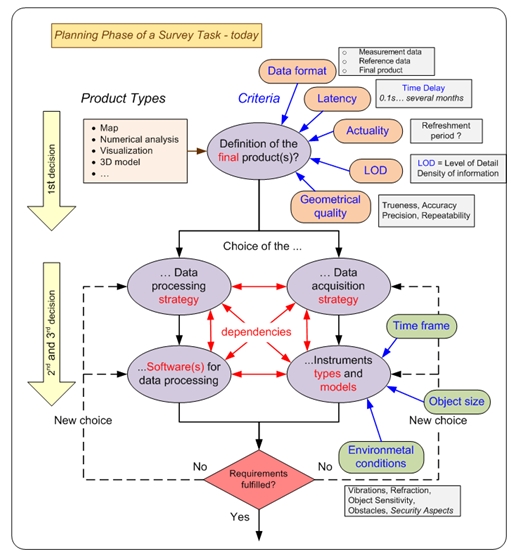

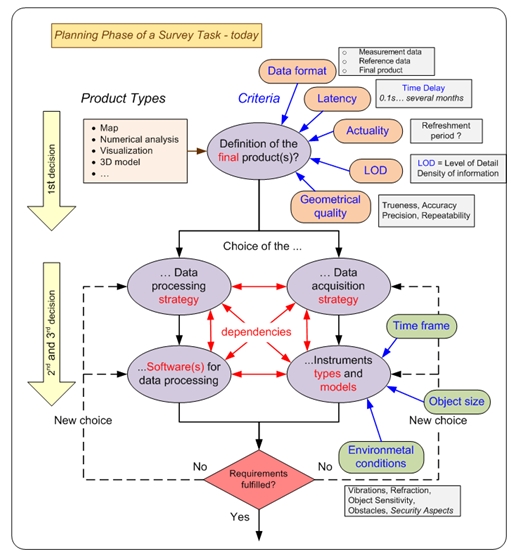

Today a surveying project will only satisfy our clients when the

planning and design phase is done with a lot of care together with the

customer (and other relevant partners) and the desired final results in

mind. One big difference from the past is the need for real decisions

before the measuring even starts (Fig. 7).

Once the planning is completed, the field work starts with the check

of the entire measurement equipment. The FIG Working Group 5.1 developed

and published – under the chairmanship of the late Jean-Marie Becker

(Sweden) – procedures in four phases for routine checks of

electro-optical distance meters (FIG, 1994). These guidelines are still

valid and the rules can easily be extended to other instruments (total

stations, GNSS-receivers). The ISO Standard 17123 (ISO, 2009) prepared

by the Technical Committee ISO/TC 172, SC 6, now describes in eight

sub-standards the field procedures for different types of geodetic

instruments, namely theodolites (part 3), electro-optical distance

meters (part 4), electronic tacheometers (part 5), optical plumbing

instruments (part 7), and GNSS field measurement systems in real-time

kinematics (RTK, part 8).

If the equipment is working correctly and the quality of the results

is within the expected range, the measuring itself can start. In general

all the data are recorded on digital media. The important rule “build

proof into the process” is already respected during the fieldwork with

first checks for mistakes. Another important part of the data analysis

is the determination of the achieved accuracy. Once all the errors have

been detected and eliminated and the accuracy of the entire data is

determined, the real data processing can start.

Fig. 7: The planning and design phase of an actual surveying

project.

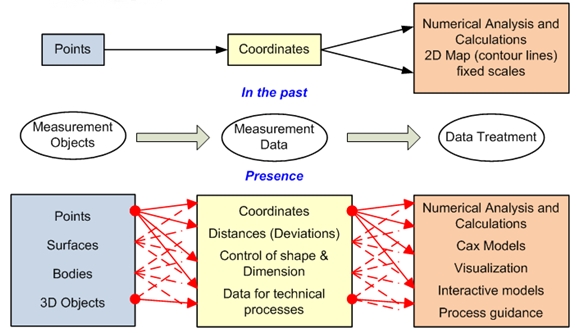

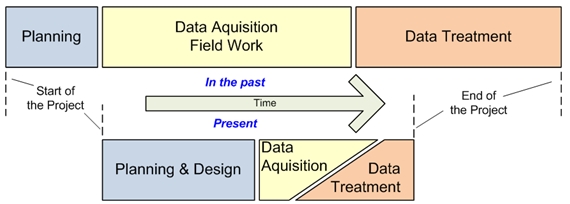

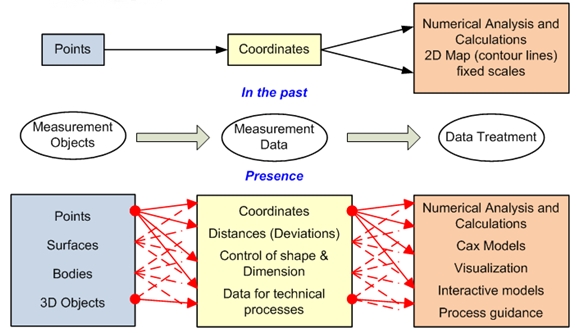

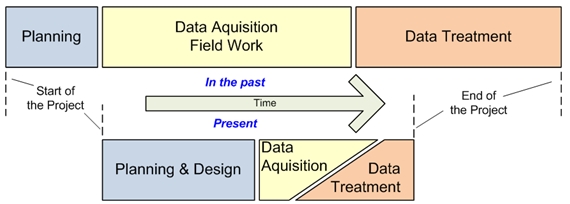

5. CHANGES IN THE OPERATIONAL REQUIREMENTS OF A SURVEYOR

In the past surveying was quite clear. We had only a few measurement

methods and for each task there was a specific instrument. In contrast

to the current situation there was no choice between different types of

instruments for the same task. The execution of all measurements was in

general guided and controlled by regulations and there was no space for

individual decisions regarding the measurement procedure. Following the

established rules directly ensured good control of the acquired data. We

determined only points – in the horizontal positions or heights – and

the final results were either a map of predetermined fixed scale or a

numerical analysis (Fig. 8a).

Fig. 8a: The surveying tasks in the past and today.

Today the possibilities and the actual demands are wider and differ

more. A surveying project can be divided roughly into three phases:

planning & design, data acquisition, and data treatment (Fig. 8b). In

former times they were executed one after the other. Today the planning

phase is – relative to the execution phase – much more extended than it

was before and the first part of the data treatment runs in parallel

with the data acquisition phase. Due to the far more efficient equipment

used for data acquisition and treatment, a project can be finished much

earlier than in past decades. At the same time the results can be used

for different purposes like planning, mapping at different scales and

with different levels of detail, volume determination, and so on.

Fig. 8b: The different phases of a surveying project (not to

scale).

6. CONCLUSIONS

The art of measurement does still exist, but it has changed

significantly. In the past it meant “mastering the instrument”; today it

should be transcribed as “mastering the entire process”. The handling of

the instrument itself has become much easier, but the demands on the

surveying engineer today are much wider and more complex. Mastering the

process starts with decisions on the optimal measurement and data

processing strategy, followed by the optimal choice of instruments

(types and models). Today we often combine different measurement

systems.

For one task there are today several potential measurement systems

available, all of them having specific advantages and inconveniencies.

This is also valid for the data processing strategies including the

choice of appropriate software products. To make the optimal choice we

also have to consider the specific side conditions for the project. In

order to make these decisions in a professional way – which is part of

the modern art of measurement – we need knowledge:

- in physics and mathematics, especially regarding the

propagation of uncertainties and adjustment computations

- about the different measurement methods (advantages,

inconveniences, dependencies, perturbations, …)

- on the efficient checking of our instruments, and finally

- about the different possibilities for data processing

(side conditions, limitations, etc.).

Once the decision on a specific strategy and concrete types of

instruments is made, the realization can start. “Push the button” is

indeed the easiest part of the field work, but there still remain some

delicate manual operations like centering, leveling, and determining the

heights of the instruments or targets.

The art of measurement was limited in the past to the precise

acquisition of data (observations!). Today the data acquisition itself

has become much easier, but this does not mean that the whole

measurement process is easy to handle and free of errors! The

measurement process today is much more complex than it was decades ago.

Therefore we need surveying experts who are able to master the entire

process of data acquisition and data processing. Each measurement task

is different and has its own characteristics. We have to take special

care with an independent check and proof of the entire measurement

system and the final results. This exactly is the modern art of

measurement.

REFERENCES

BYRNE, P.M. & KELLY, G. (2007) “The ABC of x, y, z – 21 Principles

for Consideration by Surveyors and Other Geospatial Professionals”, FIG

Working Week, Hong Kong.

DEPENTHAL, C. (2004) “Stativbewegungen bei der Verwendung von

Robottachymetern”. Allgemeine Vermessungs-Nachrichten (AVN), pp.

227–233.

HELMHOLTZ, H. v. (1887) “Messen und Zählen erkenntnistheoretisch

betrachtet”.

INGENSAND, H. (2001) “Systematische Einflüsse auf praktische

Messungen mit dem Tachymeter und Digitalnivellier”. 54. DVW-Seminar

“Qualitätsmanagement in der geodätischen Messtechnik”.

DVW-Schriftenreihe, Band 42, pp. 120–137.

STAIGER, R. (1998) “Zur Überprüfung moderner Vermessungsinstrumente”.

Allgemeine Vermessungs-Nachrichten 105 (11/12), 365 – 372.

FIG: (1994) Publication No. 9, “Recommended Procedures for Routine

Checks of Electro-Optical Distance Meters”, available as pdf-download,

2007.

http://www.fig.net/pub/figpub/pubindex.htm

ISO Standard 17123 (2009)

http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_tc_browse.htm?commid=53732.

CONTACTS

Prof. Dr.-Ing. Rudolf Staiger

University of Applied Sciences Bochum

Lennershofstrasse 140

44801 Bochum

GERMANY

Tel. +49-234-32-10547

Email:

rudolf.staiger@hs-bochum.de

Web site: www.hs-bochum.de

|